Chip supply is tight, Nissan cuts Mississippi factory output

According to foreign media reports, the shortage of semiconductor chips has disrupted global automobile production and has now reached Nissan’s Canton plant in Mississippi. This plant is responsible for the production of Nissan's pickup trucks, cars and commercial trucks.

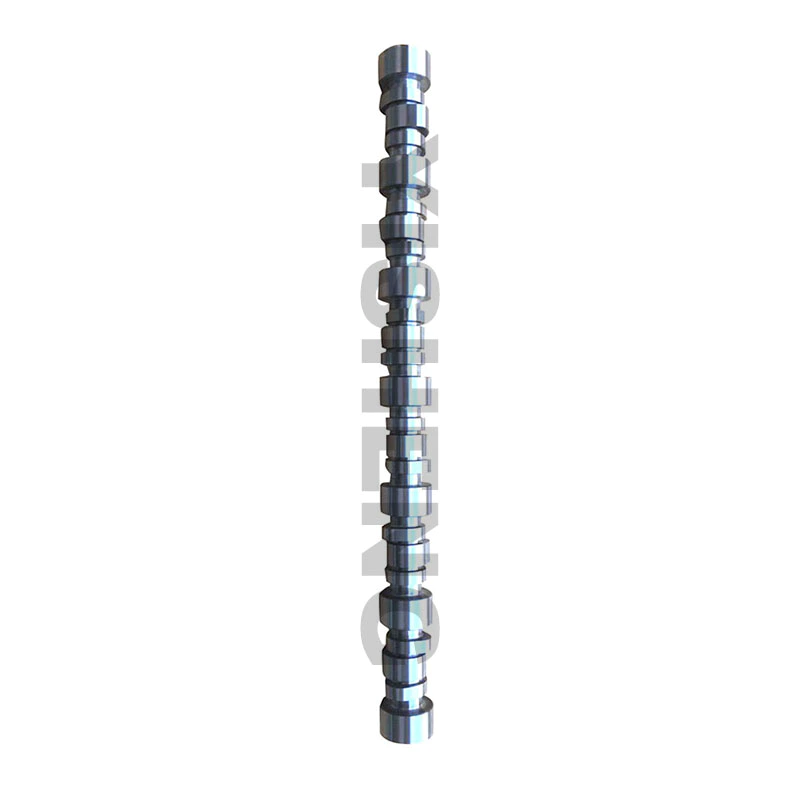

2021 Frontier (Image source: Nissan)

Later on January 29, a Nissan spokesperson said in an email: “Due to the global semiconductor shortage, Nissan is adjusting production capacity at our North American factory. We continue to work closely with our supplier partners to monitor Situation, assess the long-term impact on the factory.'

A factory memo shows that Nissan’s Canton plant has stopped production of Frontier and Titan pickup trucks at the end of January for two days, and the pickup truck production line will be closed on February 8. According to data from industry consulting company AutoForecast Solutions, Nissan produces approximately 410 medium- and full-size pickup trucks at the plant every day. At the end of this summer, Nissan's mid-size Frontier will undergo a major facelift. This is the first time this model has been facelifted since 2004.

In addition, the memo shows that the assembly of Altima at the Canton plant has also been affected, and Nissan has cut overtime in January and production of Altima on Saturday.

Nissan’s larger Tennessee plant in Smyrna, Tennessee, has not been affected by the lack of cores. The plant mainly produces crossovers, including Nissan’s best-selling compact crossover Rogue.

The shortage of chips has affected the production of some automakers in the United States, including Ford and Toyota. Industry organizations predict that the chip supply shortage will continue into the second quarter, and may even be in the second half of 2021.